Engraving

How does laser technology work?

How Does a Laser Cutting and Engraving Machine Work?

Blog Introduction: Laser cutting and engraving machines are becoming increasingly popular in industrial and commercial applications. But what is a laser cutting and engraving machine, and how does it work? In this blog post, we explore the science behind laser cutting and engraving machines, including what makes them so powerful and precise.

What Is a Laser Cutting Machine?

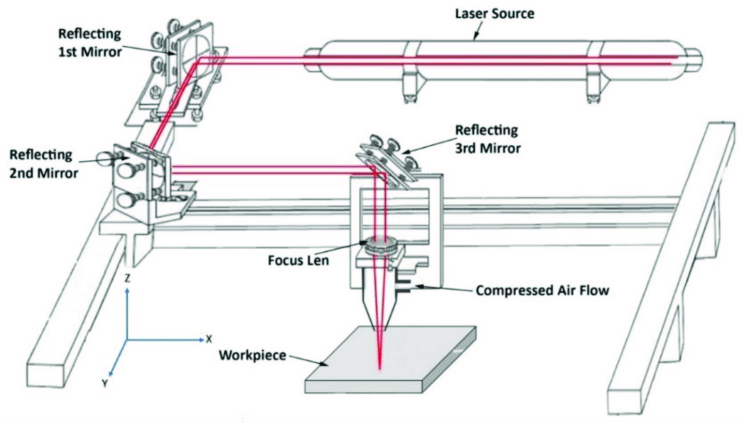

A laser cutting machine is a device that uses an amplified beam of light to cut through materials as thin as paper or as thick as 25mm of wood or acrylic. The beam is generated by a powerful gas-filled tube called a CO2 laser, which produces an intense, narrow beam of light that can be focused down to very small spot sizes. This beam is then directed at the material to be cut or engraved.

The Benefits of Laser Cutting & Engraving Machines

Laser cutting and engraving machines offer several advantages over traditional cutting methods such as saws or blades. These include increased precision, faster production times, improved safety due to lack of contact between the tool and the material, less waste material produced during the process because no additional force is applied to the material being cut or engraved, and versatility due to their ability to be used on multiple materials with varying thicknesses.

How Do Laser Cutting Machines Work?

Laser cutting machines work by using an amplified beam of light (usually infrared or ultraviolet) that is concentrated into a narrow straight line. The most common type of laser used in modern machines is a Carbon Dioxide (CO2) laser which produces heat in the form of light capable of vaporizing materials with melting points up to hundreds of degrees Celsius. The CO2 laser produces its beam in a sealed glass tube filled with gas particles that are energized by applying high-voltage electricity; this causes them to produce light energy which can then be directed at the material being cut or engraved.

The intensity of the beam can also be adjusted depending on the type of material being worked on; for example harder materials require higher-intensity beams while softer materials require lower-intensity beams in order to prevent damage caused by overheating. Additionally, different power settings can provide better results when working with different types of materials such as wood, plastic or metal; this ensures maximum accuracy when working with each type of material.

1. Laser cutting machines use an amplified beam of light (usually infrared or ultraviolet) to cut through material.

2. The most common type of laser used is a Carbon Dioxide (CO2) laser which produces heat capable of vaporizing materials with melting points up to hundreds of degrees Celsius.

3. The CO2 laser produces its beam in a sealed glass tube filled with gas particles that are energized by applying high voltage electricity, producing light energy that can be directed at the material being engraved or cut.

4. Different power settings are available for adjusting depending on the type and hardness of the material; this ensures maximum accuracy when working with various types and thicknesses of materials such as wood, plastic or metal.

5. Laser engraving machines offer several advantages over traditional cutting methods due to their increased precision, faster production times, improved safety and less waste produced during the process due to no additional force applied to the material being worked on

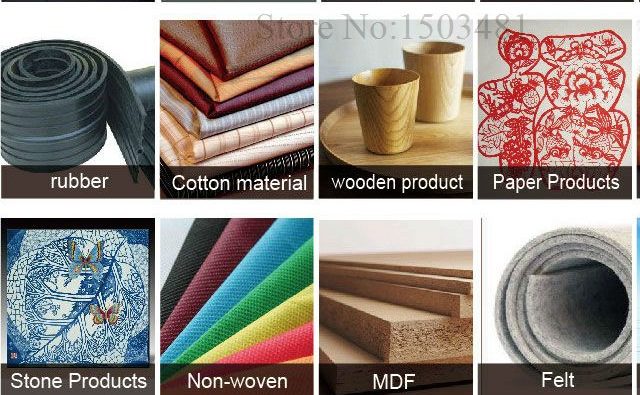

Materials commonly used with a CO2 laser cutting and engraving machine.

1. Wood

2. Cardboard

3. Some plastics

4. Leather

5. Foam

6. Acrylic

7. Glass

8. Fabric and Textiles

9. Paper

10. Stone/Tile/Slate

Conclusion:

In conclusion, laser cutting and engraving machines are incredibly versatile tools capable of producing precise cuts across multiple types of materials quickly and efficiently – all thanks to their use of high-powered lasers! By understanding how these devices work you can get more out of your own machine for whatever task you need it for! Whether you’re looking for intricate detail in woodworking projects or large scale industrial fabrication jobs – knowing how your laser cutter works will give you the best possible results! With their impressive abilities there’s no wonder why these tools have become so popular in recent years!

The main benefits of using a laser cutting and engraving machine include increased precision, faster production times, improved safety due to the lack of contact between the tool and the material, less waste material generated in the process compared to traditional methods because no additional force is applied to the material being cut or engraved, and versatility due to their ability to work on multiple materials with varying thicknesses.

A laser allows for more accurate and intricate detailing than saws or blades, as it can precisely adjust power settings based on the type and hardness of the material. This ensures maximum accuracy when working with different types of materials such as wood, plastic or metal. Furthermore, since laser beams are highly focused, they require minimal energy input which reduces manufacturing costs by eliminating any unnecessary wear and tear on tools or machines. Additionally, lasers provide a cleaner cut surface finish which results in smoother edges compared to traditional cutting methods.

In addition to these practical advantages, laser cutting machines can also be used for creative purposes such as decoration or arts & crafts projects; these machines allow users to create beautiful patterns or designs on various materials with ease. This opens up an entire world of possibilities when it comes to creating unique pieces that stand out from the rest!

Why not check out our engraved gifts in our shop https://yorkshireinvites.co.uk/product-category/engraving-and-gifts/