Engraving, Uncategorized

What’s the difference between laser etching and laser engraving?

What’s the difference between laser etching and laser engraving?

Laser etching and laser engraving are two common techniques used in the manufacturing industry to mark or engrave various materials. Both techniques use high-powered lasers to etch or engrave patterns or text onto different surfaces. However, there are some key differences between the two processes.

Firstly, laser etching is a marking method that creates raised surfaces by heating and melting the material’s micro-surface. Laser etching uses a lower power setting to only mark the outer layer of the material, creating a subtle, matte finish. The technique is often used to add branding, serial numbers, or other small details to products like electronics, jewellery, and medical devices.

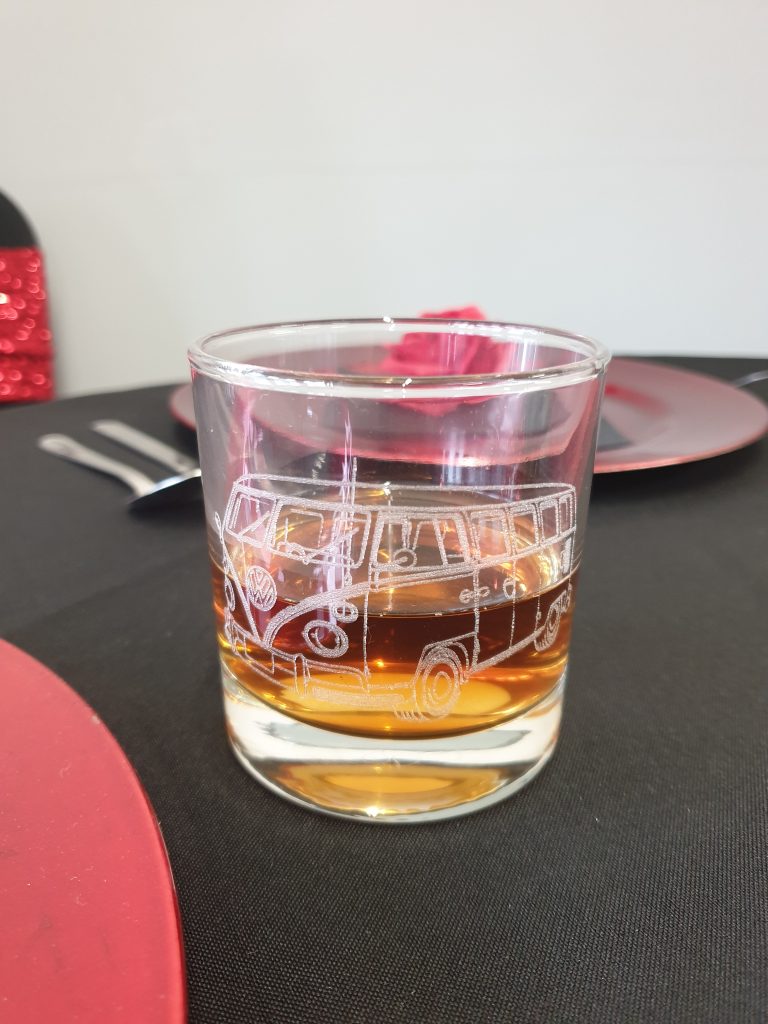

On the other hand, laser engraving is a more precise technique that involves removing material from the surface of the material. The laser essentially vaporizes the material to create deep, permanent grooves, leaving a high-contrast finish on a wide range of materials like wood, plastic, and leather. Laser engraving is used to create detailed designs, logos, and text on a variety of items from trophies and signage to personalised gifts and industrial parts.

Another significant difference between laser etching and laser engraving is the type of materials they work best on. Laser etching is more suited to materials like glass, ceramic, and certain types of metals (using a chemical coating to mark metals black). These materials can be easily marked without being damaged by the laser’s heat. Laser engraving, on the other hand, is better suited for softer materials like wood, acrylic, and leather, as the laser can remove the surface with precision and accuracy.

The cost and time it takes to produce markings also differ between these two techniques. Laser etching is generally faster, more cost-efficient, and requires less labour/finishing than laser engraving. Since laser etching works by melting the material’s surface, it doesn’t produce debris, which makes it a cleaner and more efficient process. Laser engraving, however, is a more laborious process, requires more setup time, and is generally more expensive than laser etching. why not check out our etched and engraved gifts in our shop. Shop Now...

Laser etching is an efficient and cost-effective method for creating markings and designs on a variety of materials. Here are some of the advantages and disadvantages of laser etching:

Advantages:

1. High precision – the laser can create very detailed and intricate markings with great accuracy, even on small or irregularly shaped surfaces.

2. Low cost – due to its simplicity and speed, laser etching is a relatively inexpensive method for marking materials.

3. Versatile – laser etching can be used on a wide range of materials, including glass, ceramics, and metals (with the use of coating chemicals).

4. Non-contact process – the laser beam does not touch the material, so there is no risk of damage or contamination from physical contact.

5. Consistent – laser etching produces very consistent results, ensuring that each item is marked in the same way.

Disadvantages:

1. Limited depth – laser etching produces raised markings, but these are relatively shallow and may not be as visible or durable as deeper engraving.

2. Limited colours – laser etching typically only produces markings in a single colour (usually white or grey), which may not be suitable for some applications.

3. Limited contrast – depending on the material and the laser etching method used, the contrast between the markings and the base material may be relatively low, making the markings less visible.

4. Limited durability – some laser-etched markings may be susceptible to fading, scratching, or other damage over time, especially if the material is exposed to harsh conditions.

5. Limited flexibility – because the laser etches the material at a fixed depth and width, it is difficult to make changes or adjustments to the markings once they have been made.

Laser engraving is a highly precise method of removing material to create deep, permanent grooves on a wide range of materials like wood, plastic, and leather. Here are some of the advantages and disadvantages of laser engraving:

Advantages:

1. Durable – laser engraving produces deep, permanent markings that are highly resistant to wear, fading, scratching, and other forms of damage. This makes it an ideal choice for industrial parts, signage, and other items that need to withstand harsh conditions.

2. High contrast – laser engraving produces markings in a high-contrast colour, usually black or dark brown, which makes them highly visible and easy to read. This is particularly useful for items like trophies and awards, where the text or logo needs to stand out.

3. Versatile – laser engraving can be used on a wide range of materials, including plastics/acrylics, wood, leather, and rubber. This makes it a versatile choice for many different applications, from personalised gifts to industrial parts.

4. Precise – laser engraving is a highly precise process that allows for intricate designs, logos, and text to be engraved with great accuracy. This makes it an ideal choice for items where precision is key.

5. Customisable – laser engraving can be used to create custom designs, logos, and text that are tailored to the specific needs of the customer. This makes it a popular choice for personalised gifts and awards.

Disadvantages:

1. Limited depth – laser engraving can only produce markings up to a certain depth, which may not be suitable for all applications. For example, it may not be deep enough for some industrial parts that need to be stamped or embossed.

2. Cost – laser engraving is generally more expensive than laser etching, due to the additional setup time and labour involved in the process.

3. Time-consuming – laser engraving is a more time-consuming process than laser etching, as it involves removing material rather than simply melting the surface. This makes it a longer process overall. Engraving involves using more power and a slower speed in the process.

4. Limited colours – laser engraving typically only produces markings in a single colour, which may not be suitable for some applications where multiple colours are required.

5. Limited materials – laser engraving is only suitable for certain types of materials, such as wood, plastic, and leather. It may not be suitable for materials that are too hard or too soft, or that are susceptible to heat damage.

In conclusion, although laser etching and laser engraving have some similarities, they are two distinct processes with different applications and results. Both techniques offer a range of possibilities for marking and engraving materials, and their advantages should be weighed up when considering which method to use. Understanding the differences between the two processes is critical to achieving the desired results accurately and cost-effectively.